Features and Specifications:

This machine may realize proper fermentation through automatic and precise control of temperature, Rh, oxygenation and time and provision of optimal and stable environment. Its application may eliminate excessive or insufficient fermentation, make the leaflets red and even, end the age of tea fermentation with traditional process, and further stabilize, uniform and upgrade tea quality. This machine is simple in operation and low in maintenance cost, and suitable for household, tea farm and tea plantations of various scales.

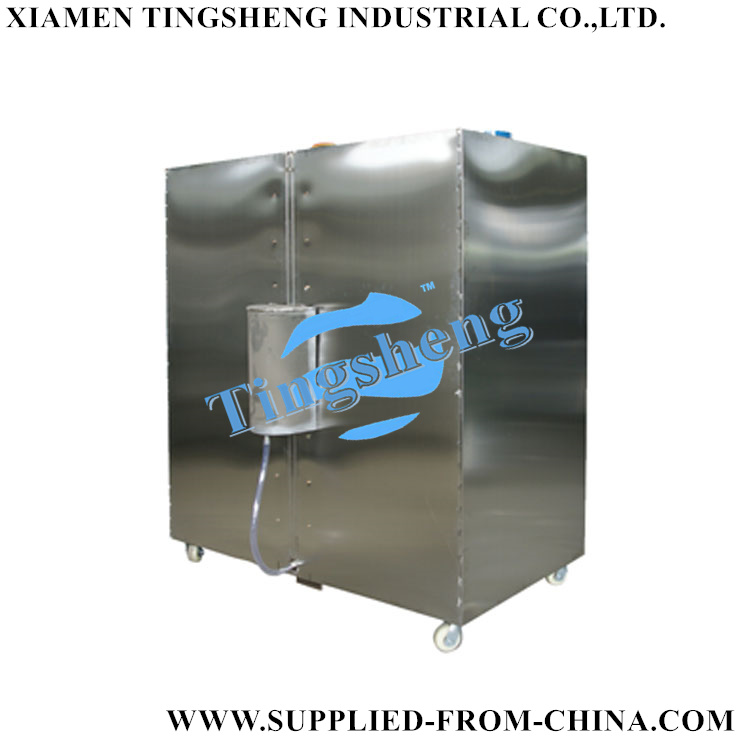

1. Use ultrasonic humidifier to ensure the humidity in the fermentation machine is controllable and adjustable.

2. Adopt a small hot air generator to ensure that the temperature inside the fermentation machine is controllable and adjustable.

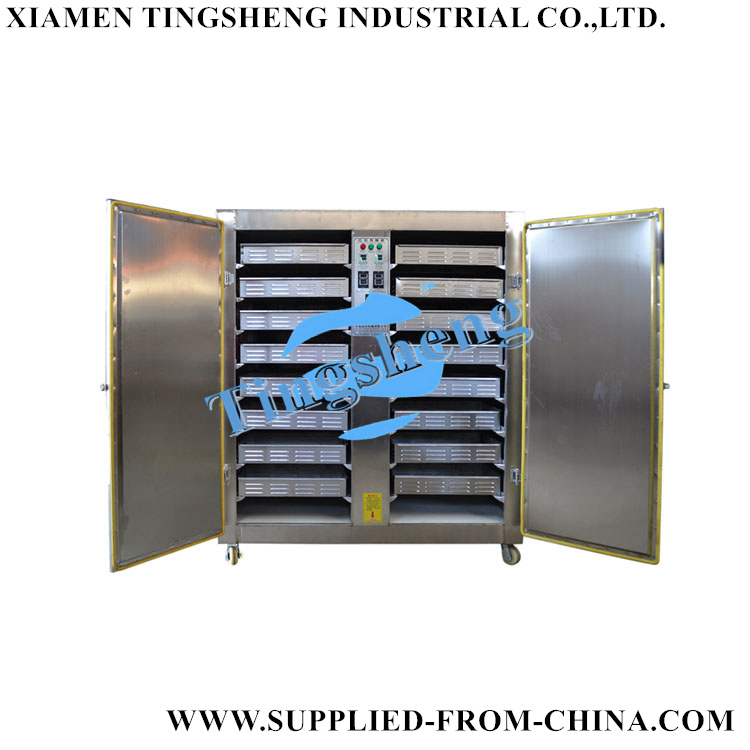

3. The parts in contact with the tea (upper and middle sections, etc.) are all made of stainless steel to ensure cleanliness.

4, fermentation time can be controlled and adjustable, the maximum fermentation time can reach 16 hours.

5. The setting and control of the main unit, humidity, temperature, etc. can be realized on one control panel.

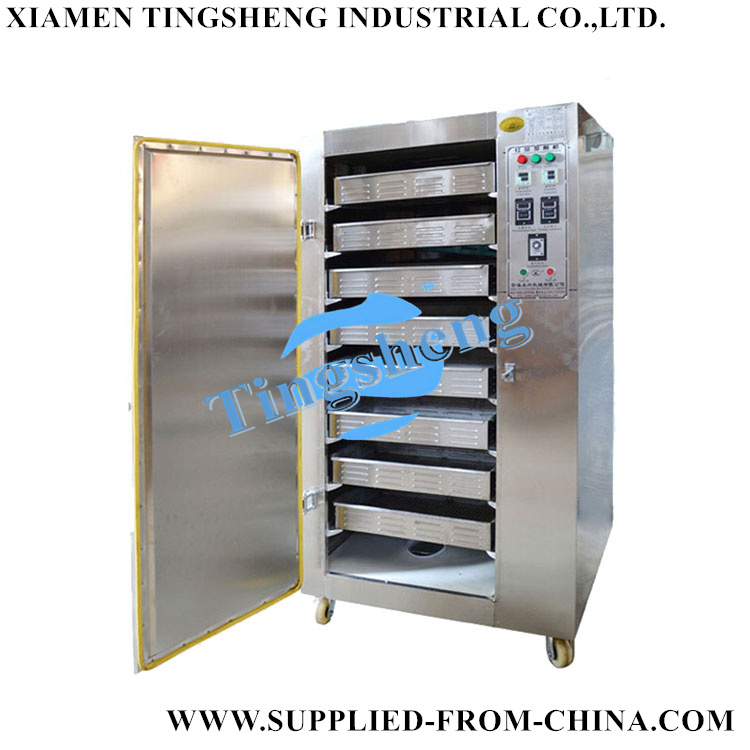

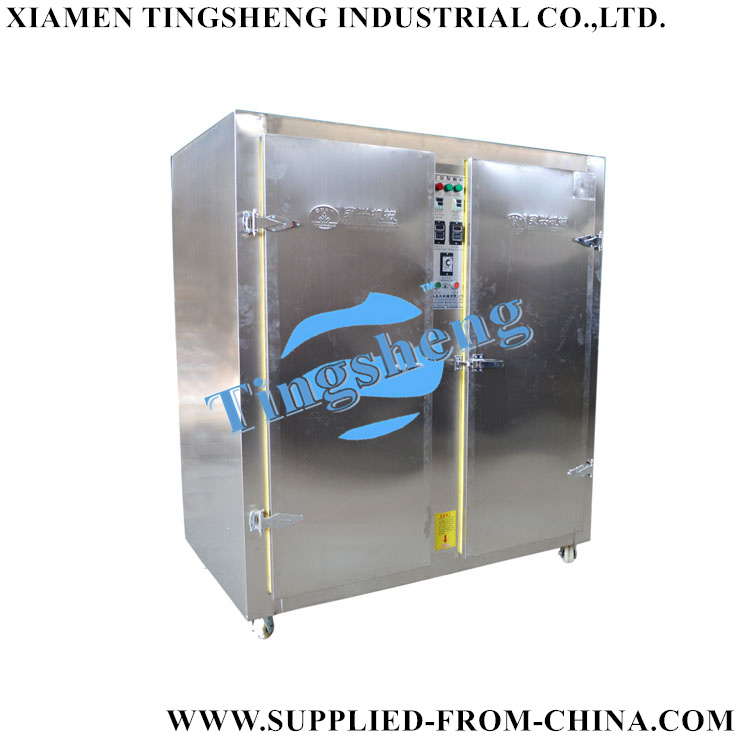

Model | Outside dimensions | Work output (calculated on basis of green leaves) | Fermentation barrel (optional) | Integral power | Work voltage |

TS-TFM-16B | 1100*950*2000mm | 175kg/ cycle | 16 pieces | 2.0kw | 220v |

TS-TFM-32B | 1600*950*2000mm | 350kg/cycle | 32 pieces | 2.0kw | 220v |

The black tea fermentation machine is designed to provide the most suitable and stable environmental conditions to complete the tea fermentation through automatic and precise control of temperature, humidity and time, avoiding the problem of over-fermentation or under-fermentation and making the tender leaves red and even in color. Thus, the tea fermentation is freed from the era of relying on the traditional process, and the quality of tea is further stabilized, unified and enhanced. This machine is easy to operate and low maintenance cost, suitable for use in family tea plantations and tea farms.

Use and operation:

1、The machine must be filled with water before working.

2, the machine works at 220 volts, black for the zero line, and to have good grounding.

3, turn on the power, turn on the power switch, the light is on, connect the inlet pipe to a stable water source on the tap water pipe, or more than 20 liters of water barrel, so that the humidifier tank can reach sufficient water level to avoid burnout due to insufficient water. When the machinery is not used, the drainage switch should be turned on to drain the water of the humidifier through the drainage pipe.

4, set a good temperature, generally about 28-30 ℃, the heating switch should be closed, when the outside ambient temperature is below 10 ℃, before opening the heating switch, so that it warms up.

5、Set the fermentation time, generally about 3-6 hours, which can be increased or decreased according to the degree of tea fermentation. After the fermentation time is completed, the alarm will indicate the completion of fermentation.

6、Special attention: the water inlet opening is always kept half open (1/2) state.

Maintenance and care:

1, the machine in use period, should be installed in accordance with the requirements of the equipment, often check the conductors have no loose phenomenon, grounding wire has a solid ground.

2,Check the main parts of the machine, accessories, fastening screws are not loose.

3,Regularly check the wear and tear of the wearing parts, consumption, test its work performance, can not be used, should be repaired or replaced in a timely manner.

4,Regularly dust the main assembly parts and accessories of this machine to maintain its good working performance.

5, the machine's door seal on the drying room to play a sealing and insulation role, not with sharp objects, blunt objects touch, and not with corrosive liquids for cleaning, so as not to damage the seal.

6, should often clean the internal and external surfaces of the machine, cleaning should be cut off before the power, wipe with a soft wet cloth or soft brush, sweep brush, do not use irritating, corrosive liquid cleaning drying room four walls and drying tray bracket.

7, the end of each use, good electric control box on the panel of each setting key position back to "0", the switch to "off".

8、When the machine is not used for a long time, the total power supply should be cut off, do a good job of cleaning, well packed and stored in a dry, ventilated room.

Pictures: